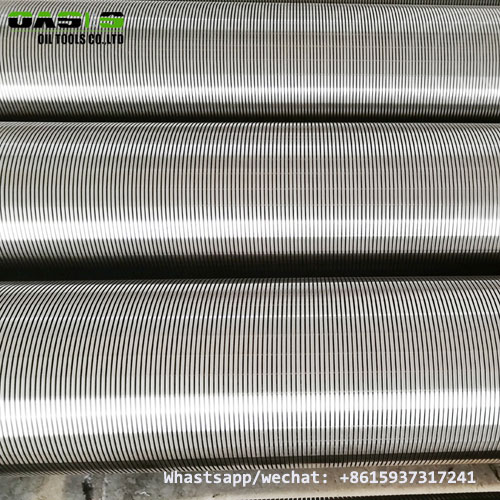

The consecutive slot of our Continuous Slot Wedge Wire wound Well Screens have more open area, and Continuous Slot Wedge Wire wound Well Screen can reduce the speed of the water entering to avoid the sand entering the screen under the great pressure, so it can filter sand better. The slot can change according to the real condition of the earth. Continuous Slot Rod Base Stainless Steel Well Screen. Continuous Slot Rod Base Stainless Steel Well Screen. Stainless steel screen,wedge wire water well screen are the work-horse of the well screen industry and have been used for over 60 years for sand control.Stainless steel screen,rod based water well screen can be used in both Gravel Pack and Stand Alone Screen applications.

Casing

Casing is the tubular structure that is placed in the drilled well to maintain the well opening. Along with grout, the casing keeps possibly contaminated surficial water from reaching the aquifer zone underground and prevents contaminants from mixing with the water. Poker texas holdem ohne anmeldung kostenlos spielen. The casing also holds back unstable earth materials so that they do not collapse into the well. Some states or local governing agencies have laws that require minimum lengths for casing.

The most common materials for well casing are carbon steel, plastic (most commonly, but not exclusively, PVC), and stainless steel. Different geologic formations and groundwater quality dictate what type of casing can be used. For example, parts of the country where hard rock lies underground are known strictly as 'steel states.'

Residents in some areas have a choice between steel and PVC, both of which have advantages. PVC is lightweight, resistant to corrosion, and relatively easy for contractors to install. However, it is not as strong and not as resistant to heat as steel. Steel, though, is susceptible to corrosion, can have scale build-up, and can cost more than PVC.

Some contractors also use concrete, fiberglass, and asbestos cement casing.

Well Caps

On the top of the casing should be anapproved well cap. It should fit snugly so debris, insects, or small animals can't find their way into the well system.

Well caps are usually aluminum or a thermoplastic, and include a vented screen so that the pressure difference between the inside and outside of the well casing may be equalized when water is pumped from the well.

The casing and cap should extend at least 12 inches above the ground. If the well is near a river or stream, it should extend at least past the flood level to prevent overflows from contaminating the groundwater.

For information on well caps,click here.

Well Screens

Events at mgm casino detroit. Well screens are filtering devices used to prevent excess sediment from entering the well. They attach to the bottom of the casing or in intercepted water-bearing zones, allowing water to move through the well, while keeping out most gravel and sand. The most popular screens are continuous slot, slotted pipe, and perforated pipe.

Perforated pipe is a length of casing that has holes or slots drilled into the pipe, often after the casing is installed, perforated in place. It is not efficient for aquifers that feature a lot of sand and gravel because it has wide openings.

Continuous slot screens are made of wire or plastic wrapped around a series of vertical rods. This configuration provides consistent, regular slot openings that can be engineered to the particle sizes found in the screened zone. Slotted pipe screens, which have the least amount of open area, feature machine-cut slots into steel or plastic casing at set distances. Both of these are typically installed with a filter pack (gravel pack) that assists in screening and stability of the well.

Pitless Adapters

Pitless adapters provide wells with a sanitary — and frost-proof — seal between the well casing and the water line running to the well system owner's house.

After a frost line is determined for the area where the well is being installed, the adapter is connected to the well casing below the frost line. Water from the well is then diverted horizontally at the adapter to prevent it from freezing.

Continuous Slot Well Screens

For more information on materials used in a water well system,contact a professional contractor in your area.

Subscribe to the monthly Private Well Owner Tip Sheet

- Company ProfileBluslot filter

- Product BrandBluslot

- RegionChina

- CategoryEnvironment - Waste Management

- MashupChina Environment - China Waste Management

- RelatedJohnson Well Screen - Water Well Screen - Well Screen Pipe

Water Well Screens consist of V-shape profile wire and the longitudinal support rods. theV wire is welded to the rods and produces a rigid unit that has high strength and minimum weight. so Water Well Screens has sturdy constriction and good mechanical property.

The V-shape section plane can avoid blockage and make sure of the unimpeded water. The consecutive slot have more open area, and it can reduce the speed of the water entering to avoid the sand entering the Water Well Screens under the great pressure, so it can filter sand better. Meanwhile, the slot of Water Well Screens can change according to the real condition of the earth.

welded cylindrical screen

The construction correspond with the follow drawings respectively

1.Stangard contruction

2.Axial wire construction

3.Internal circumferential wire construction

4.inverwire construction

Advantages

Production process continuity: V-shaped profile wires creating slots which enlarge inwardly and therefore avoid clogging and minimize downtime.

Low maintenance costs: Separation at the screen surface which can easily cleaned by scraping or back washing.

Maximum process output: Precise and continuous slot openings resulting in accurate separation without loss off media.

Low operational costs: Large open area with an effective flow, high yield and a low pressure drop (dP)

Long live: Welded at each intersection creating a strong and durable screen.

Reduced installation costs: supporting constructions eliminating costly support media and enabling a maximum flexibility in the design of components.

Chemical and thermal resistant: A variety of corrosion resistant stainless steel materials and many exotic alloys suitable for high temperatures and pressures.

Casing is the tubular structure that is placed in the drilled well to maintain the well opening. Along with grout, the casing keeps possibly contaminated surficial water from reaching the aquifer zone underground and prevents contaminants from mixing with the water. Poker texas holdem ohne anmeldung kostenlos spielen. The casing also holds back unstable earth materials so that they do not collapse into the well. Some states or local governing agencies have laws that require minimum lengths for casing.

The most common materials for well casing are carbon steel, plastic (most commonly, but not exclusively, PVC), and stainless steel. Different geologic formations and groundwater quality dictate what type of casing can be used. For example, parts of the country where hard rock lies underground are known strictly as 'steel states.'

Residents in some areas have a choice between steel and PVC, both of which have advantages. PVC is lightweight, resistant to corrosion, and relatively easy for contractors to install. However, it is not as strong and not as resistant to heat as steel. Steel, though, is susceptible to corrosion, can have scale build-up, and can cost more than PVC.

Some contractors also use concrete, fiberglass, and asbestos cement casing.

Well Caps

On the top of the casing should be anapproved well cap. It should fit snugly so debris, insects, or small animals can't find their way into the well system.

Well caps are usually aluminum or a thermoplastic, and include a vented screen so that the pressure difference between the inside and outside of the well casing may be equalized when water is pumped from the well.

The casing and cap should extend at least 12 inches above the ground. If the well is near a river or stream, it should extend at least past the flood level to prevent overflows from contaminating the groundwater.

For information on well caps,click here.

Well Screens

Events at mgm casino detroit. Well screens are filtering devices used to prevent excess sediment from entering the well. They attach to the bottom of the casing or in intercepted water-bearing zones, allowing water to move through the well, while keeping out most gravel and sand. The most popular screens are continuous slot, slotted pipe, and perforated pipe.

Perforated pipe is a length of casing that has holes or slots drilled into the pipe, often after the casing is installed, perforated in place. It is not efficient for aquifers that feature a lot of sand and gravel because it has wide openings.

Continuous slot screens are made of wire or plastic wrapped around a series of vertical rods. This configuration provides consistent, regular slot openings that can be engineered to the particle sizes found in the screened zone. Slotted pipe screens, which have the least amount of open area, feature machine-cut slots into steel or plastic casing at set distances. Both of these are typically installed with a filter pack (gravel pack) that assists in screening and stability of the well.

Pitless Adapters

Pitless adapters provide wells with a sanitary — and frost-proof — seal between the well casing and the water line running to the well system owner's house.

After a frost line is determined for the area where the well is being installed, the adapter is connected to the well casing below the frost line. Water from the well is then diverted horizontally at the adapter to prevent it from freezing.

Continuous Slot Well Screens

For more information on materials used in a water well system,contact a professional contractor in your area.

Subscribe to the monthly Private Well Owner Tip Sheet

- Company ProfileBluslot filter

- Product BrandBluslot

- RegionChina

- CategoryEnvironment - Waste Management

- MashupChina Environment - China Waste Management

- RelatedJohnson Well Screen - Water Well Screen - Well Screen Pipe

Water Well Screens consist of V-shape profile wire and the longitudinal support rods. theV wire is welded to the rods and produces a rigid unit that has high strength and minimum weight. so Water Well Screens has sturdy constriction and good mechanical property.

The V-shape section plane can avoid blockage and make sure of the unimpeded water. The consecutive slot have more open area, and it can reduce the speed of the water entering to avoid the sand entering the Water Well Screens under the great pressure, so it can filter sand better. Meanwhile, the slot of Water Well Screens can change according to the real condition of the earth.

welded cylindrical screen

The construction correspond with the follow drawings respectively

1.Stangard contruction

2.Axial wire construction

3.Internal circumferential wire construction

4.inverwire construction

Advantages

Production process continuity: V-shaped profile wires creating slots which enlarge inwardly and therefore avoid clogging and minimize downtime.

Low maintenance costs: Separation at the screen surface which can easily cleaned by scraping or back washing.

Maximum process output: Precise and continuous slot openings resulting in accurate separation without loss off media.

Low operational costs: Large open area with an effective flow, high yield and a low pressure drop (dP)

Long live: Welded at each intersection creating a strong and durable screen.

Reduced installation costs: supporting constructions eliminating costly support media and enabling a maximum flexibility in the design of components.

Chemical and thermal resistant: A variety of corrosion resistant stainless steel materials and many exotic alloys suitable for high temperatures and pressures.

Water Well Continuous Slot Screen

- Contact Personkevin

- Telephone17772525335

- Fax Number

- Websitehttps://meshfiltro.com/

- Post Code053600

- AddressEconomic Development Zone, Hengshui City, Hebei Province, China.

- Online MapBluslot filter Map & Directions

Continuous Slot Well Screen

- SellOffer household food waste disposer

- SellTransformer Oil Filtration Processing Machine

- SellTransformer Oil Purification Degasification System

- SellTransformer Oil Filtration Processing Machine

- SellUsed Hydraulic Oil Purification Treatment Plant

- Sellvacuum insulating oil recycling

- SellTransformer Oil Filtration Processing

- SellEngine oil recycling

- SellJZS Engine oil recycling system

- SellSeries JZS Engine oil recycling system

- SellSeries JZS Engine oil recycling system

- SellSeries ZYD Double-stage vacuum transformer oil recycling